Membrane Switches Over Explained: A Comprehensive Guide to Their Advantages

Membrane layer switches over stand for a advanced and versatile solution for developing individual interfaces across a selection of markets. As sectors progressively seek reliable and trustworthy control interfaces, understanding the details benefits and applications of membrane layer switches over ends up being important.

What Are Membrane Layer Switches?

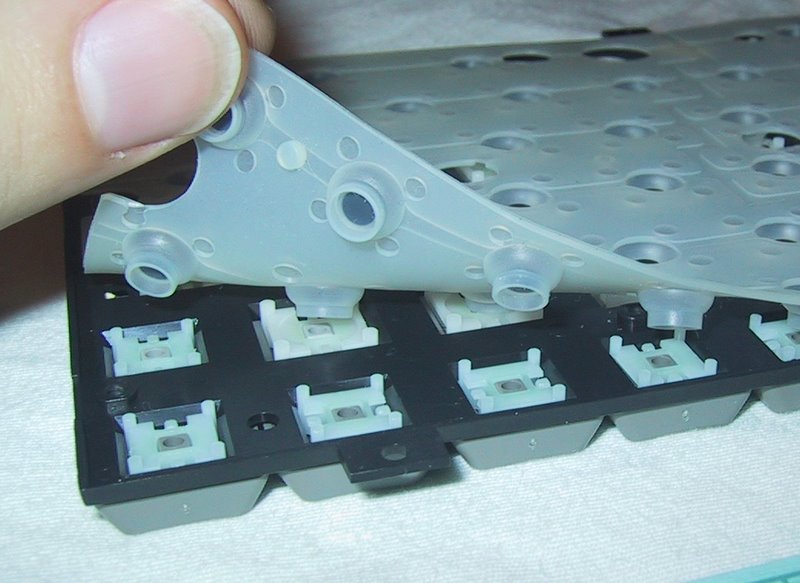

When stress is put on the membrane layer switch, the layers make contact, completing an electrical circuit. This simple device allows for a vast array of applications, from customer electronic devices to industrial machinery. Membrane layer buttons are typically designed to be water resistant and resistant to dirt and pollutants, making them ideal for atmospheres where sturdiness is crucial.

Furthermore, the flexibility of the materials made use of in membrane layer switches assists in cutting-edge styles that can adapt different shapes and dimensions. This versatility contributes to their popularity in diverse areas, consisting of clinical tools, auto controls, and home appliances. Generally, membrane changes represent a vital aspect in contemporary interface innovation, bridging the gap between users and digital systems.

Trick Benefits of Membrane Switches

Amongst the myriad of interface options available, membrane switches over stand out for their unique combination of advantages. One of the primary benefits is their compact and lightweight layout, which permits for assimilation right into a variety of devices without including considerable mass. This is especially useful in applications where room is restricted.

Furthermore, membrane switches over deal toughness and resistance to ecological elements. They are generally created with products that can stand up to moisture, dirt, and different chemicals, making them suitable for rough problems. This longevity adds to a much longer life expectancy compared to traditional mechanical buttons.

An additional considerable benefit is the versatility in modification. Membrane buttons can be printed with different graphics, shades, and structures, permitting tailored layouts that meet particular branding or practical requirements. This versatility includes the number of layers and circuit choices, giving engineers with several arrangements.

Furthermore, the responsive responses offered by some membrane changes boosts customer experience, making them a lot more instinctive to run. The simplicity of cleansing and upkeep further solidifies membrane switches as a functional selection in both customer and commercial applications. In general, these essential benefits make them a favored remedy for many designers and makers

Applications in Numerous Industries

How do membrane layer buttons locate their place across varied industries? Their adaptability and capability make them integral elements in industries varying from medical care to consumer electronic devices. In medical tools, membrane layer switches are used for their simplicity of cleansing and resistance to contamination, ensuring hygiene in environments where sterility is important.

In the customer electronic devices industry, these switches provide sleek, user-friendly interfaces that boost item aesthetic appeals while preserving durability versus damage. Automotive applications gain from membrane layer changes also, where they are made use of in control panels and control board, using reliable performance in tough conditions.

Furthermore, commercial machinery uses membrane buttons for control board because of their robustness, capacity to endure rough environments, and customizable designs that accommodate certain functional requirements. The food industry leverages membrane layer buttons for their simplicity of use and resistance to spills, making certain operational performance in hectic setups.

Eventually, the adaptability of membrane layer switches throughout these diverse applications highlights their necessary role in modern-day technology, boosting user communication while meeting industry-specific needs. Their continued advancement guarantees further assimilation into arising areas and ingenious products.

Style and Customization Alternatives

The style and customization alternatives offered for membrane buttons are vital for customizing interfaces to meet specific user demands and aesthetic preferences. These switches can be developed in various forms, dimensions, and layouts, enabling seamless combination right into varied applications. The flexibility in design indicates that manufacturers can produce special user interfaces that boost usability and preserve brand identity.

Custom-made graphics, shades, and appearances can be applied to the surface of the membrane layer button, giving a possibility for branding and user engagement. Furthermore, backlighting choices, such as LED lighting, can be incorporated to enhance exposure in low-light problems, therefore boosting functionality.

Practical components can also be customized, consisting of tactile comments and actuation pressure, which can be readjusted to match various customer communications. The choice of products, such as polyester or polycarbonate, permits variations in toughness and environmental resistance, look at this web-site dealing with the certain needs of various industries.

Ultimately, the comprehensive layout and personalization capacities of membrane layer switches enable firms to develop visually appealing and straightforward user interfaces, making certain that their items fulfill both useful and visual demands properly. Membrane Switches.

Considerations for Implementation

Implementing membrane layer changes needs careful factor to consider of different factors to make sure optimal performance and customer experience. One of the main factors to consider is the designated application setting. Factors such as exposure to dampness, extreme temperature levels, and chemical compounds can significantly impact the button's performance and long life. Picking materials that endure these problems is crucial.

One more crucial facet is the button's style and format. Ensuring that the tactile feedback and actuation force align with individual assumptions improves functionality. Carrying out individual testing can supply beneficial understandings right into the ideal style.

Additionally, compatibility with electronic elements should be evaluated. The switch's circuitry need to align with the overall system architecture, ensuring dependable signal transmission and reducing disturbance.

Moreover, production methods and prices must be examined. The choice between customized designs and basic versions can affect both advice budget plan and lead time.

Last but not least, take into consideration repair and maintenance. Membrane layer switches may call for particular cleaning and care treatments to preserve their look and functionality with time. By resolving these considerations, companies can carry out membrane buttons that meet their functional requirements while supplying a positive customer experience.

Conclusion

In conclusion, membrane changes stand for a versatile and resilient control interface suitable for a large array of applications throughout multiple markets. Membrane Switches. As innovation proceeds to advance, the relevance of membrane switches in contemporary gadgets continues to be substantial, offering both performance and visual appeal.

Membrane changes stand for a sophisticated and flexible remedy for developing customer interfaces throughout a selection of sectors.Understanding the fundamental components of modern electronic interfaces, membrane switches are a page type of user interface device that consist of flexible, thin layers of material. Generally, membrane layer switches over stand for a crucial aspect in modern-day user interface modern technology, connecting the void in between users and electronic systems.

Amongst the myriad of user interface alternatives offered, membrane changes stand out for their distinct combination of advantages.The design and personalization choices offered for membrane layer buttons are critical for customizing user interfaces to fulfill specific customer needs and aesthetic choices.